Shanghai's C919 Smart Mega Factory Revolutionizes Aircraft Production

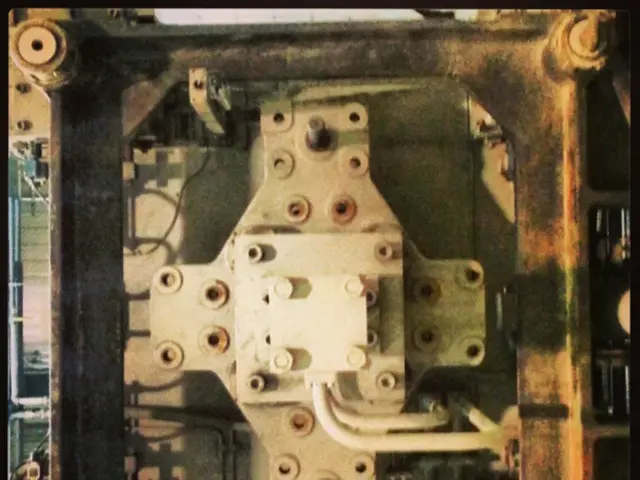

A groundbreaking project in Shanghai is revolutionising aircraft manufacturing. Researchers from Shanghai Jiao Tong University, the Chinese Academy of Sciences, and the Aviation Industry Corporation of China (AVIC) have developed an industrial network for the C919 Smart Mega Factory. This innovative system, published in the IEEE Transactions on Industrial Informatics journal, is transforming the production process with real-time tracking and high-fidelity digital twin technology.

At the heart of this smart factory lies a real-time tracking system that monitors every plane part, tool, and technician. This is made possible by a 5G-enabled industrial network system, ensuring millisecond-level responsiveness. One key application is tool and parts tracking, preventing misplacement due to human error or fatigue.

The 5G network supports real-time video analytics from hundreds of cameras. It scans footage for unsafe behaviours and alerts supervisors instantly, ensuring top-notch safety checks. This system aims to prevent issues like missing bolts or oversights that may slip through manual checks.

The digital twin technology creates a virtual replica of the aircraft and its assembly environment. It is continuously updated with live data from the production floor, reducing quality issues and speeding up assembly.

The C919 Smart Mega Factory in Shanghai is setting new standards in aircraft manufacturing. With its real-time tracking, high-fidelity digital twin, and 5G-enabled network, it ensures precision, speed, and safety in the production process. This innovative approach is poised to shape the future of industrial manufacturing.

Read also:

- India's Pragmatic Budget: Sitharaman Aims to Revitalise Growth, Alleviate Distress

- Eric Dane Diagnosed with ALS, Advocates for ACT for ALS

- Deepwater Horizon Oil Spill: BP Faces Record-Breaking Settlement - Dubbed 'Largest Environmental Fine Ever Imposed'

- Aragon Energy Sector Unites to Push for RDL 7/2025 Validation