Russia's innovative liquid metal nuclear fuel design is set to challenge the limits of rapid nuclear reactors.

The Russian state-owned nuclear energy corporation, Rosatom, is set to introduce a new nuclear fuel assembly, the OS-5, in the BN-600 reactor at the Beloyarsk nuclear power plant. This innovative fuel assembly, designed for use in fourth-generation fast neutron reactors, is a significant step forward in Rosatom's "Proryv" (Breakthrough) project, aiming to establish the technologies for a closed nuclear fuel cycle.

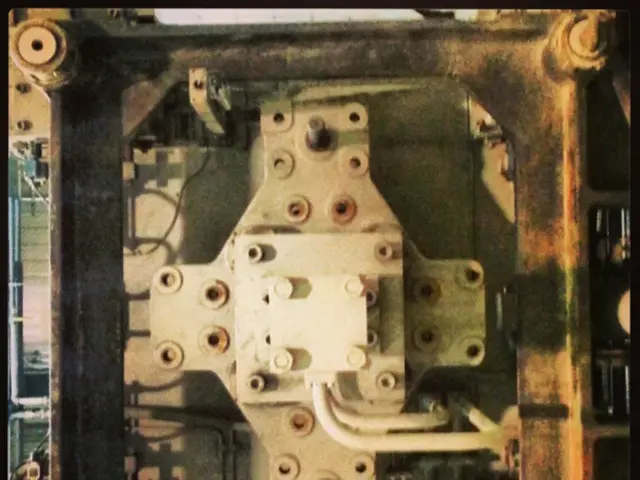

The OS-5 assembly, manufactured by Rosatom, features mixed nitride uranium-plutonium (SNUPP) fuel with a liquid metal sublayer. This design is projected to result in lower fuel operating temperatures while maintaining coolant parameters, a development that could potentially improve the operational reliability and economic profile of the fuel.

The reduced thermal expansion of the uranium-plutonium fuel pellet is expected due to the design change. This could lead to higher burnup values, a measure of fuel efficiency, indicating how much energy is extracted from the fuel. Higher burnup values, in turn, lead to longer fuel cycles and reduced waste per unit of energy generated.

The BREST-OD-300 fast neutron reactor, a key part of the "Proryv" project, will serve as the central facility of a Pilot Demonstration Energy Complex. This complex will also include facilities for on-site fuel fabrication, re-fabrication, and reprocessing.

The latest development in the OS-5 fuel assembly's design involves the inclusion of a liquid metal sublayer to modify the performance characteristics of the fuel elements. This innovation is part of Rosatom's long-term plan to develop a larger, commercial-scale 1200 MWe version known as the BN-1200M, should the 300 MWe demonstration unit prove successful.

Mikhail Skupov, deputy director general of the Bochvar Institute, stated the goal of gradually increasing the burnup depth to an average value of 12%. This ambitious target underscores Rosatom's commitment to advancing nuclear technology and reducing the volume and long-term radiotoxicity of final nuclear waste.

However, it is worth noting that the manufacturer of the new SNUPP nuclear fuel used in the OS-5 fuel rod design for Generation 4 fast neutron reactors is not publicly specified in available sources. Additionally, the innovative fuel assembly must receive approval from Rostekhnadzor before its use.

The introduction of the OS-5 fuel assembly marks a significant milestone in Rosatom's ongoing efforts to push the boundaries of nuclear technology. With its focus on efficiency, safety, and waste reduction, the OS-5 assembly could potentially pave the way for a new era in nuclear power generation.

Read also:

- Deepwater Horizon Oil Spill: BP Faces Record-Breaking Settlement - Dubbed 'Largest Environmental Fine Ever Imposed'

- Cars' Environmental Impact Explained

- The German automobile sector requires advancement in environmentally friendly steel production

- Fossil fuels remain the primary energy source for heating in Baden-Württemberg