BMW's Gen6 Batteries: New Plants, New Tech, and a Data-Driven Leader

The BMW Group is expanding its electric vehicle capabilities with the sixth generation of high-voltage batteries, known as Gen6. Before mass production, the company tests and optimizes production processes at pilot plants in Parsdorf, Hallbergmoos, and the Research and Innovation Centre in Munich. Leading this effort is Patrick Zimmermann, a dual role data scientist and IT project manager.

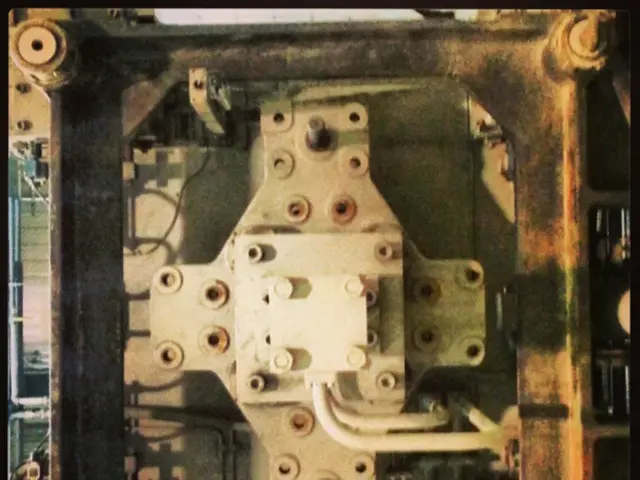

Zimmermann's primary role involves analyzing and interpreting data to enhance the production process of Gen6 high-voltage accumulators. He also oversees the implementation of IT systems and project coordination to ensure smooth production workflows. His interdisciplinary team manages data provision, edge applications, and analytics platforms, processing both numerical data and visual representations from equipment, with a zero-defect approach to battery production.

The new plants for Gen6 high-voltage batteries allow for greater IT design freedom and bigger technological leaps compared to integrating new solutions into existing plants. The BMW Group uses OPC UA interface technology for plant connectivity, enabling the creation of standardized digital twins and data transfer to BMW clouds. This advancement, along with improved energy density, charging speed, and range, marks significant technological progress in high-voltage batteries for electric vehicles.

The BMW Group is investing in five assembly sites across three continents for the production of Gen6 high-voltage batteries. Patrick Zimmermann's expertise in battery production technologies and strong IT knowledge, focusing on software architectures for data analytics and AI, is crucial for the success of this expansion. His leadership ensures efficient data processing and optimal production workflows, driving the company's electric vehicle ambitions.