BASF's Zhanjiang Site Nears Completion, Boosting Asian Petrochemical Presence

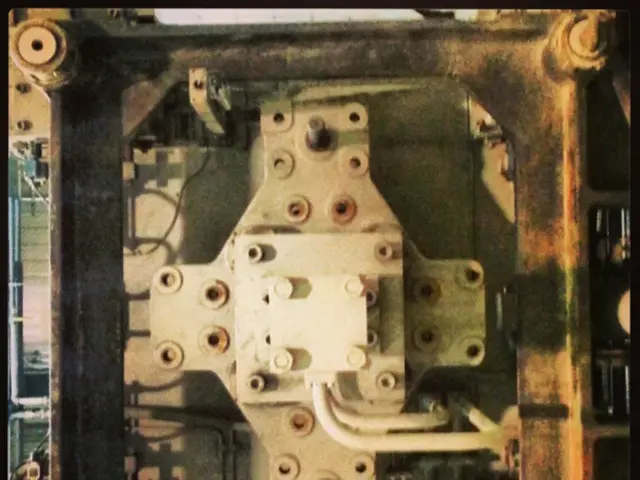

BASF's Zhanjiang site is nearing completion, with the steam cracker and indoor plants making significant progress. The steam cracker, with an annual ethylene capacity of 1 million tons, is set to be fully operational by the end of 2025. Meanwhile, the butyl acrylate plant, with an annual capacity of 400,000 tons, has already begun production, making its first tanker delivery just six days after starting up.

The Zhanjiang site's location near customers promises shorter delivery routes and increased supply security. This strategic positioning aligns with BASF's 'Winning Ways' strategy, aiming to meet growing demand for high-quality petrochemical products in Asia. The butyl acrylate plant started production on August 11, ahead of schedule, further boosting BASF's leading position in the acrylics segment. The steam cracker and downstream petrochemical facilities at the site have reached mechanical completion, marking a significant milestone in the project's progress.

The total investments for the Zhanjiang site were reduced by 1.3 billion euros to around 8.7 billion euros, under the original budget. This was primarily achieved through cost savings in procurement and a corporate-wide effort to reduce expenses. The final investment costs were lowered from the initially planned €10 billion to about €8.7 billion.

With the steam cracker and butyl acrylate plant nearing full operation, BASF's Zhanjiang site is poised to strengthen the company's position in the Asian petrochemical market. The site's progress, despite cost reductions, underscores BASF's commitment to strategic investments and operational efficiency.

Read also:

- India's Pragmatic Budget: Sitharaman Aims to Revitalise Growth, Alleviate Distress

- Eric Dane Diagnosed with ALS, Advocates for ACT for ALS

- Deepwater Horizon Oil Spill: BP Faces Record-Breaking Settlement - Dubbed 'Largest Environmental Fine Ever Imposed'

- Aragon Energy Sector Unites to Push for RDL 7/2025 Validation